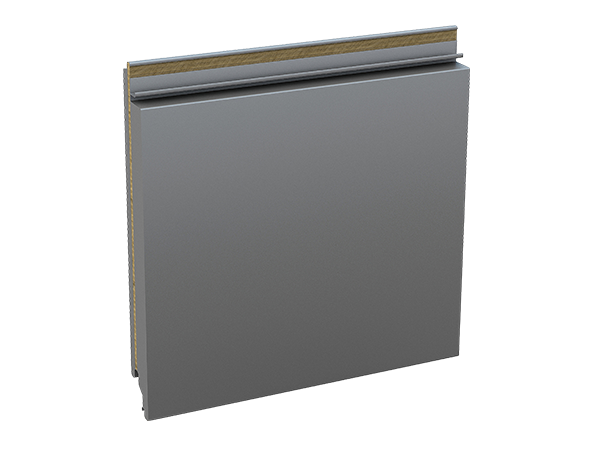

DSR-J Customization Options

DSR-J Specifications

| Panel Width | 300mm – 1200mm* |

| Panel Thickness | 50mm – 200mm |

| Reveal Width | 2mm – 75mm |

| Surface Finish | Smooth, Embossed, Striated |

| Outer Metal Layer Thickness | 0.6 – 1.0mm |

| Inner Metal Layer Thickness | 0.5 – 1.0mm |

| Mineral Wool Weight Capacity | Standard 140KG/m3 |

| Substrates | Stainless Steel, Titanium Zinc Plate, Color-Coated Steel Plate, Aluminum, and more. |

*Other non-standard panel widths are available. For details, please don't hesitate to contact your CENTRIA International Sales Manager or kindly complete our Enquiry Form, and a representative will be in touch shortly.

DSR-J Customization Options

DSR-J Specifications

| Panel Width | 300mm – 1200mm* |

| Panel Thickness | 50mm – 200mm |

| Reveal Width | 2mm – 75mm |

| Surface Finish | Smooth, Embossed, Striated |

| Outer Metal Layer Thickness | 0.6 – 1.0mm |

| Inner Metal Layer Thickness | 0.5 – 1.0mm |

| Mineral Wool Weight Capacity | Standard 140KG/m3 |

| Substrates | Stainless Steel, Titanium Zinc Plate, Color-Coated Steel Plate, Aluminum, and more. |

*Other non-standard panel widths are available. For details, please don't hesitate to contact your CENTRIA International Sales Manager or kindly complete our Enquiry Form, and a representative will be in touch shortly.